The “14. Oktobar” factory from Kruševac is actively working on its modernization process as part of a broader strategy for digitization and automation of production, with a clear goal of positioning itself as a “smart factory” in accordance with Industry 4.0 standards.

This strategic move marks a significant milestone in the company’s operations, given the growing demands of the modern market and the need for faster, more efficient, and more precise processes. One of the key steps in the factory’s transformation was the acquisition and installation of 12 state-of-the-art CNC machines, model HYUNDAI WIA L3100L, at the beginning of 2025. These machines offer high precision and flexibility, along with the ability to perform multiple operations in a single cycle, significantly reducing production time, manual interventions, and errors, while simultaneously increasing productivity and the quality of the final product.

The HYUNDAI WIA L3100L model is equipped with a Fanuc CNC controller that provides an intuitive user interface and integrates easily with existing systems. Technical specifications include a maximum machining diameter of up to 500 mm, machining length of up to 1,500 mm, and a turret with 10 positions for fast and automatic tool changes. This investment has significantly enhanced the factory’s technological level and strengthened its competitiveness both in domestic and international markets.

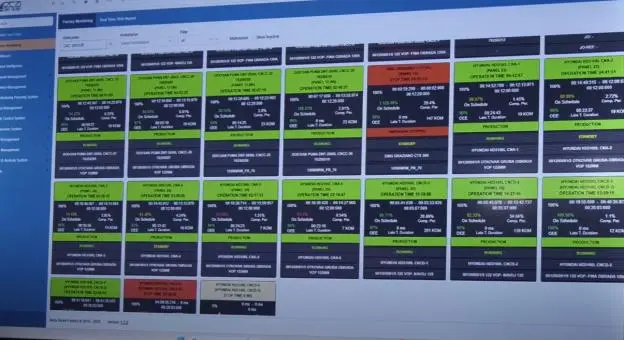

In addition to mechanical modernization, the factory is also undergoing a digital transformation of its entire production process, implementing advanced software solutions, artificial intelligence, and analytical tools for real-time performance monitoring. These solutions enable faster decision-making, better resource planning, and more efficient management of all production phases.

A major step forward is the implementation of the “smart factory” concept—a digital system that allows monitoring of all employee and machine activities through smart devices. Workers log in via tablets, and the system records the start and end of work, breaks, shift changes, and any production downtime. This enables completely transparent and accurate monitoring of the productivity of each individual and the entire team.

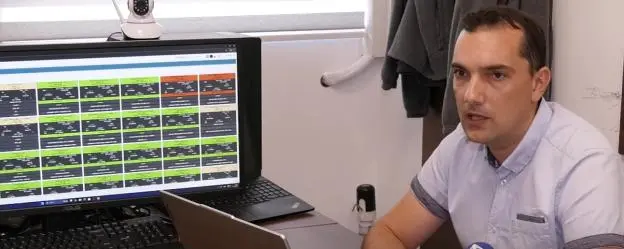

“The benefit is that we have increased productivity, efficiency, and product quality. We’ve reduced the number of corrections, and with comprehensive process and personnel monitoring, we receive automatic reports that support both management and operational staff. We are among the first factories in Serbia to implement this kind of full-scale digital monitoring,” says Nenad Milosavljević, IT Manager at the “14. Oktobar” factory, responsible for the system’s operation.

As a member of the industrial company Czechoslovak Group, the “14. Oktobar” factory confirms its commitment to innovation, sustainable development, and strengthening Serbia’s industrial potential through these technological advancements, setting standards for the next generation of domestic manufacturing.

Source: https://www.sd.rs/biz/vesti/digitalizacija-cnc-tehnologije-i-pametna-fabrika-14-oktobar-idu-u-korak-s-industrijom-buducnosti-2025-08-21

Photos: Property of the CSG Group